This article dives into the 7 key differences between copper and aluminum wires, highlighting their features, applications, and which one is the best affordable solution for different needs in Pakistan.

When it comes to electrical wiring, the choice of material plays a vital role in determining safety, efficiency, and cost. Copper and aluminum wires are two of the most commonly used options worldwide, each with its own advantages and limitations. For industries and homeowners alike, understanding these differences is critical, especially in Pakistan, where affordability often influences purchasing decisions.

Copper wires are known for their excellent conductivity and durability, making them a preferred choice for residential and commercial applications. Aluminum wires, on the other hand, are lighter and more affordable, which has made them popular in large-scale and budget-conscious projects. With material prices fluctuating over the past few years, finding the right balance between cost and performance has become increasingly important.

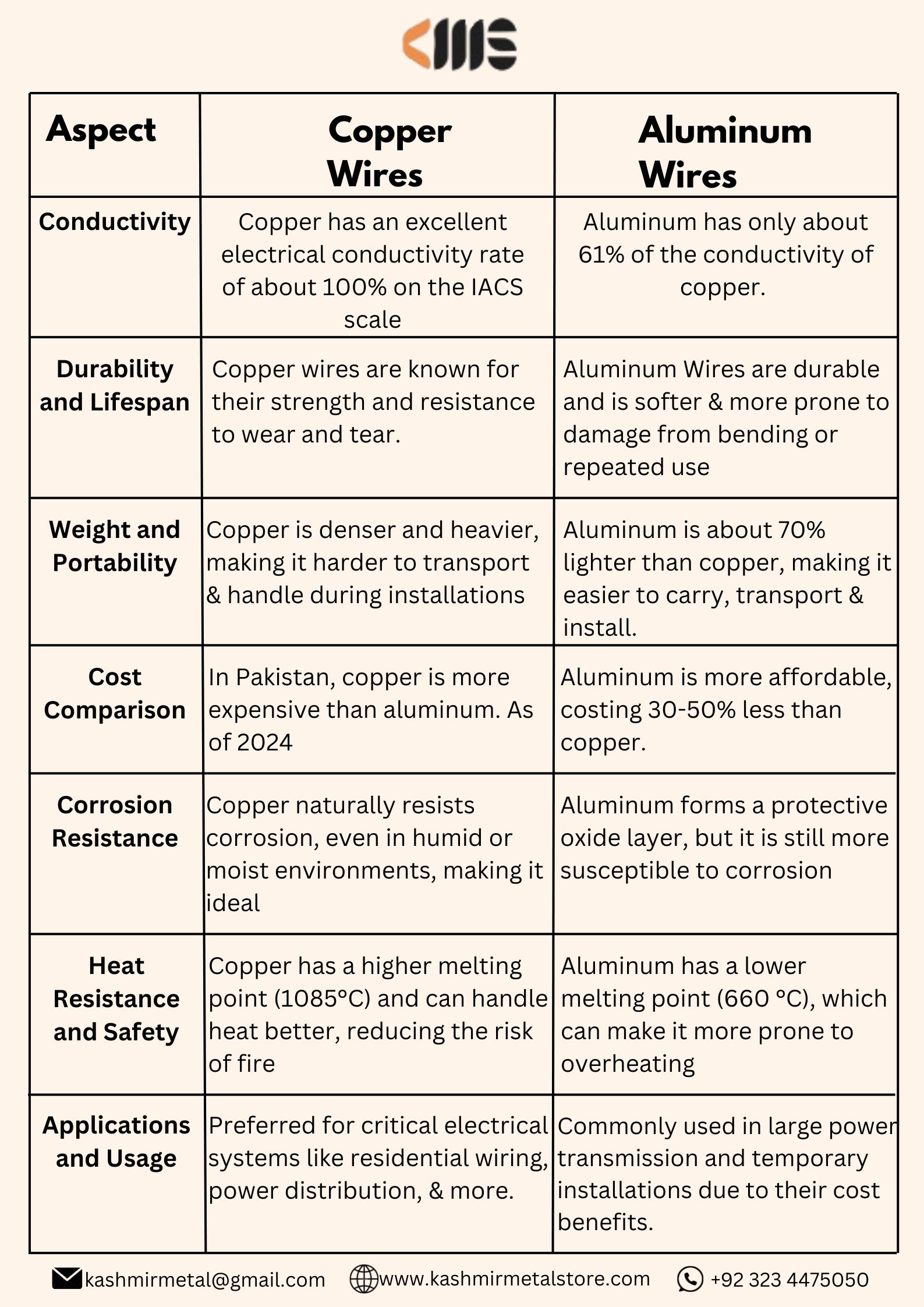

1. Conductivity

-

Copper Wires:

Copper has an excellent electrical conductivity rate of about 100% on the IACS (International Annealed Copper Standard) scale. This makes it the gold standard for wiring, particularly in power-critical environments.

-

Aluminum Wires:

Aluminum has only about 61% of the conductivity of copper. To achieve the same current carrying capacity, aluminum wires must be thicker.

Which is Better?

Copper is the better conductor, ensuring more reliable performance, but at a higher cost.

2. Durability and Lifespan

-

Copper Wires:

Copper Wires Known for their strength and resistance to wear and tear, copper wires can last for 20–50 years with proper care. They are less likely to break or corrode over time.

-

Aluminum Wires:

Aluminum Wires, While durable, aluminum is softer and more prone to damage from bending or repeated use. Its lifespan is usually around 10–30 years, depending on usage.

Best for Longevity: Copper is more durable and reliable over the long term.

3. Weight and Portability

-

Copper Wires:

Copper is denser and heavier, making it harder to transport and handle during installations.

-

Aluminum Wires:

Aluminum is about 70% lighter than copper, making it easier to carry, transport, and install.

Ideal for Lightweight Needs: Aluminum is the better option when weight is a concern.

4. Cost Comparison

-

Copper Wires:

Globally and in Pakistan, copper is significantly more expensive than aluminum. As of 2023, the price of copper wires has increased by 10-15% due to high demand.

-

Aluminum Wires:

Aluminum is more affordable, costing 30–50% less than copper. This makes it a popular choice for budget-conscious buyers in Pakistan.

According to an analysis by the World Bank, the rising demand for copper in global markets is a key driver of its price hikes, especially in emerging economies.

Most Affordable: Aluminum wins in terms of cost, especially for large-scale projects.

5. Corrosion Resistance

-

Copper Wires:

Copper naturally resists corrosion, even in humid or moist environments, making it ideal for outdoor and underground installations.

-

Aluminum Wires:

Aluminum forms a protective oxide layer, but it is still more susceptible to corrosion, particularly in certain environments with high moisture or chemical exposure.

Best in Harsh Conditions: Copper provides better resistance to corrosion over time.

6. Heat Resistance and Safety

-

Copper Wires:

Copper has a higher melting point (1085 °C) and can handle heat better, reducing the risk of fire caused by overheating.

-

Aluminum Wires:

Aluminum has a lower melting point (660 °C), which can make it more prone to overheating under high current loads.

According to a study by the National Fire Protection Association (NFPA), wiring materials with higher heat resistance, like copper, significantly reduce fire risks in residential and commercial installations.

Safety Choice: Copper is the safer option for wiring in high-temperature environments.

7. Applications and Usage

-

Copper Wires:

Preferred for critical electrical systems like residential wiring, power distribution, and heavy machinery, where reliability is non-negotiable.

-

Aluminum Wires:

Commonly used in large-scale power transmission, overhead cables, and temporary installations due to their lightweight and cost benefits.

Usage in Pakistan:

For residential wiring and long-term projects, copper remains the top choice. For cost-effective solutions in large-scale projects, aluminum is often preferred.

Which is the Best Affordable Solution in Pakistan?

Given the economic situation and rising material costs in Pakistan, the best choice depends on the application:

-

For Residential Use:

Copper is the best choice despite being more expensive. Its durability, safety, and conductivity make it a reliable investment for long-term use.

-

For large-scale or temporary projects:

Aluminum wires are more affordable and practical for short-term or large-scale projects where budget constraints are significant.

Cost Insight (2024):

- Copper wires in Pakistan are priced at Rs. 2,500-3,000 per kilogram, whereas aluminum wires cost around Rs. 1,200-1,500 per kilogram. This price gap has made aluminum a more viable option for budget-conscious buyers.

Market Trends in Pakistan

- Copper Demand: Copper remains the preferred material for residential wiring, despite rising costs. The demand for copper wires increased by 5% in 2022 due to urban expansion projects.

- Aluminum Usage: Aluminum wires have seen a 20% increase in usage in industrial projects due to their affordability and ease of installation.

- Safety Concerns: The use of aluminum in older residential projects has decreased due to safety concerns, with many homeowners opting for copper instead.

Advantages of Buying from Reliable Suppliers

Whether you choose copper or aluminum, sourcing materials from a trusted supplier is crucial. For example, the best metal store in Pakistan offers:

- High-quality materials tested for durability and performance.

- Competitive pricing to fit your budget.

- Expert guidance to help you make the right decision.

For reliable options, check out:

Conclusion: Making the Right Choice

Choosing between copper and aluminum wires depends largely on your specific requirements, whether they are for residential use, commercial setups, or large-scale industrial projects. Copper wires, with their superior conductivity, durability, and safety features, are undoubtedly the best choice for long-term reliability. They are ideal for critical applications like residential wiring and heavy machinery, where performance and safety are paramount.

However, aluminum wires offer a significant advantage in terms of affordability. For projects where budget constraints are a concern, such as large-scale power transmission or temporary setups, aluminum is a practical alternative. Despite its lower conductivity and durability compared to copper, aluminum’s lightweight and cost-effective nature make it a valuable option in the right contexts.

In Pakistan, where economic considerations often shape decisions, the choice often comes down to weighing long-term benefits against immediate costs. If you’re planning a large-scale project and need to cut costs without compromising too much on performance, aluminum may be your best bet. For homeowners and businesses prioritizing safety and longevity, copper remains the superior option despite its higher price.

To ensure you’re getting the best materials for your needs, always buy from a trusted supplier. The best metal store in Pakistan offers high-quality copper and aluminum wires, competitive prices, and expert advice to help you make the right choice.

Making an informed decision today will save you from potential challenges in the future. Choose wisely, and invest in materials that will support your projects for years to come.